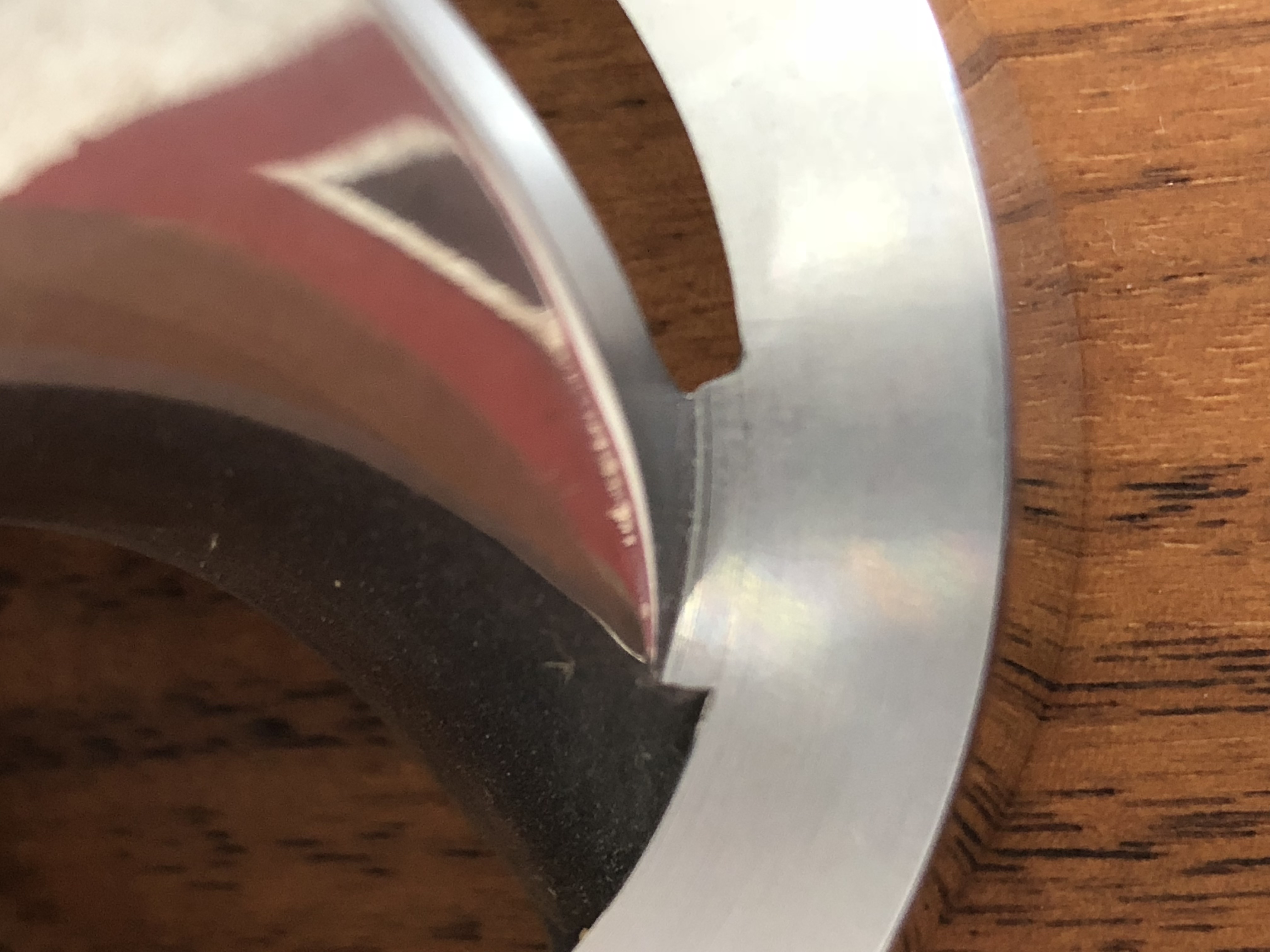

Helical Static Mixer

Manufactured by Samhwa Mixing Tech, Korea

JLS helical static mixers provide a continuous in-line mixing of fluids or gases with alternating helical elements, each set 90˚ to its adjacent element for thorough blending over a specified length for a wide variety of materials.

JLS helical mixers are custom designed for each application. The number of mixing elements is determined by the specific requirements of the application. Helical mixers can be jacketed or electrically heated and supplied with fixed or removable element rods. Also, edge seal type is provided for special applications. Sizes range from 2 mm to more than 2 meters in diameter.

The first helical element rotates the flow in one direction, then the direction is reversed at the next element. This action creates a further mixing effect, promoting product uniformity.

The flow is forced to be inverted completely so that the stream is continuously moved to the center to the inner pipe wall and back again.

Due to very smooth shape, perfect surface finishing (Ra 0.6 – 0.8) and no-gap welding, there are no dead spots in the mixer for any product to hang up or degrade.

Helical mixer is used for film or other polymer applications. Extremely tight tolerances and perfect fit avoid any dead spots for product build-up. Available in all custom specified sizes and ring dimensions.